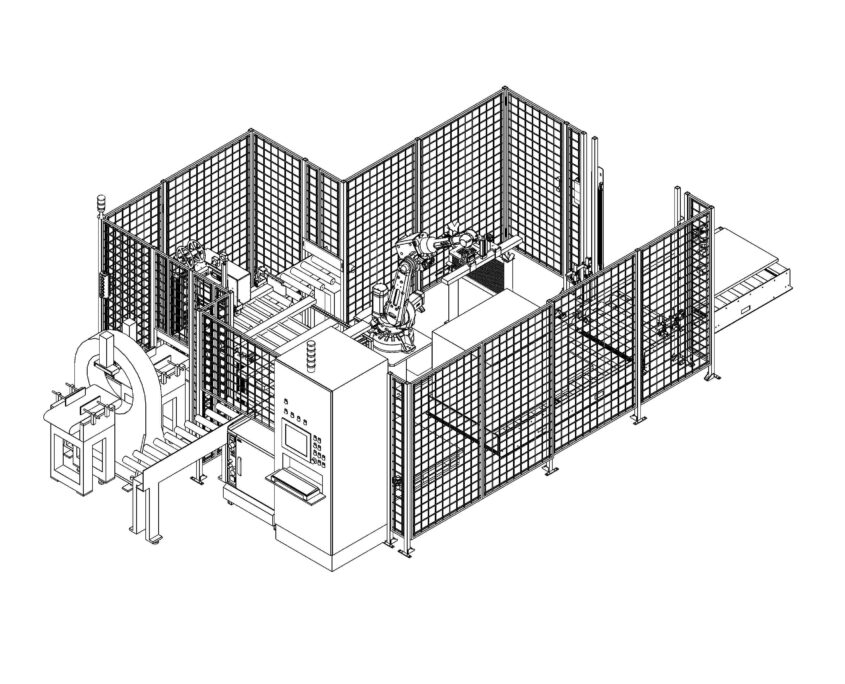

Robotized palletizing system for door frames

Project goals:

Design and manufacture of a custom robotized palletizing system for the automation of packaging activities

- Integration with an existing line

- Layout optimization

- Flexible solution, ideal for frequent production changeovers

Find out how Tecnodinamica stepped into this project:

Main features

- Powered roller conveyor for material feeding connected to the existing line

- Automatic labelling system

- Robotized palletizing system with custom grippers designed for the specific application

- Spacers magazine with minimum level sensor

- Roller conveyor for pallet off-loading

- Electrical control panel with touch screen

- Custom parametric software for recipe management

- Possible software integration with upstream stations

- Customized HMI interface

- Real-time process controls

- Remote assistance and process diagnostic

- Industry 4.0 requirements and integration with enterprise management systems

Indicative overall dimensions

- 7.700 x 4.300 mm (safety fences included)

Tecnodinamica activity

- Mechanical design

- Electrical design

- Software design and robot programming

- Mechanical assembly

- Wiring on board machine and electrical control panel

- In-house start-up and test

- Start-up and training at the production site