Automatic assembly

Our custom solutions for automatic assembly are the result of a detailed analysis carried out in cooperation with the customer related to the products to be assembled, the components, production process, logistics and quality requirements.

From materials feeding, to their assembly, up to the testing and unloading of finished products, all phases are designed to ensure cycle times, quality and plant reliability always in line with customer needs and the highest market standards.

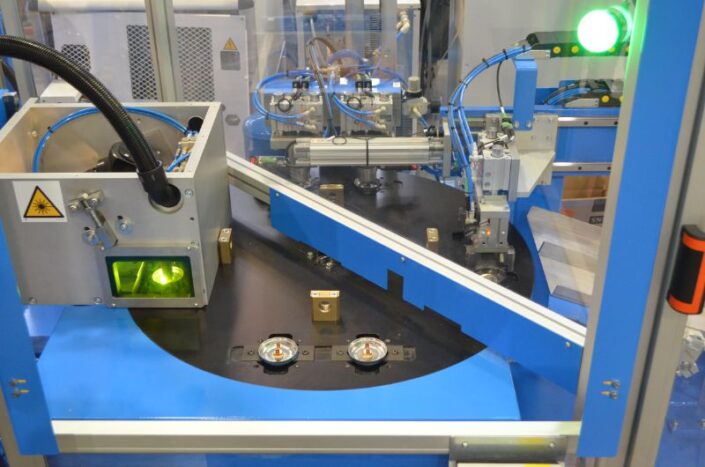

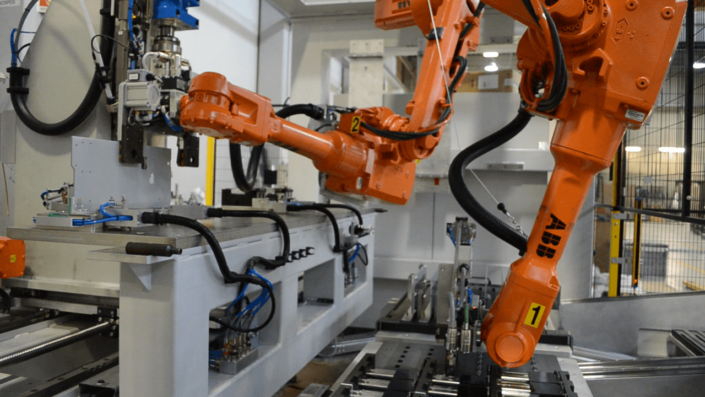

Possible solutions include the development of semi-automatic equipment, fully automatic assembly systems, robot cells, linear or rotating table platforms. From mechanics to software, common feature is the extreme reliability and customization.

Our experiences include:

- Multiple feeding systems such as linear transfers, vibrators, manipulators etc.

- Mechanical couplings

- Riveting systems

- Laser welding

- Mechanical, electrical and pneumatic testing systems

- Integration with vision systems for selection and control

Find out more about our case histories

All the solutions shown have been designed based on customers’ requirements. They have illustrative and non-exhaustive purpose.