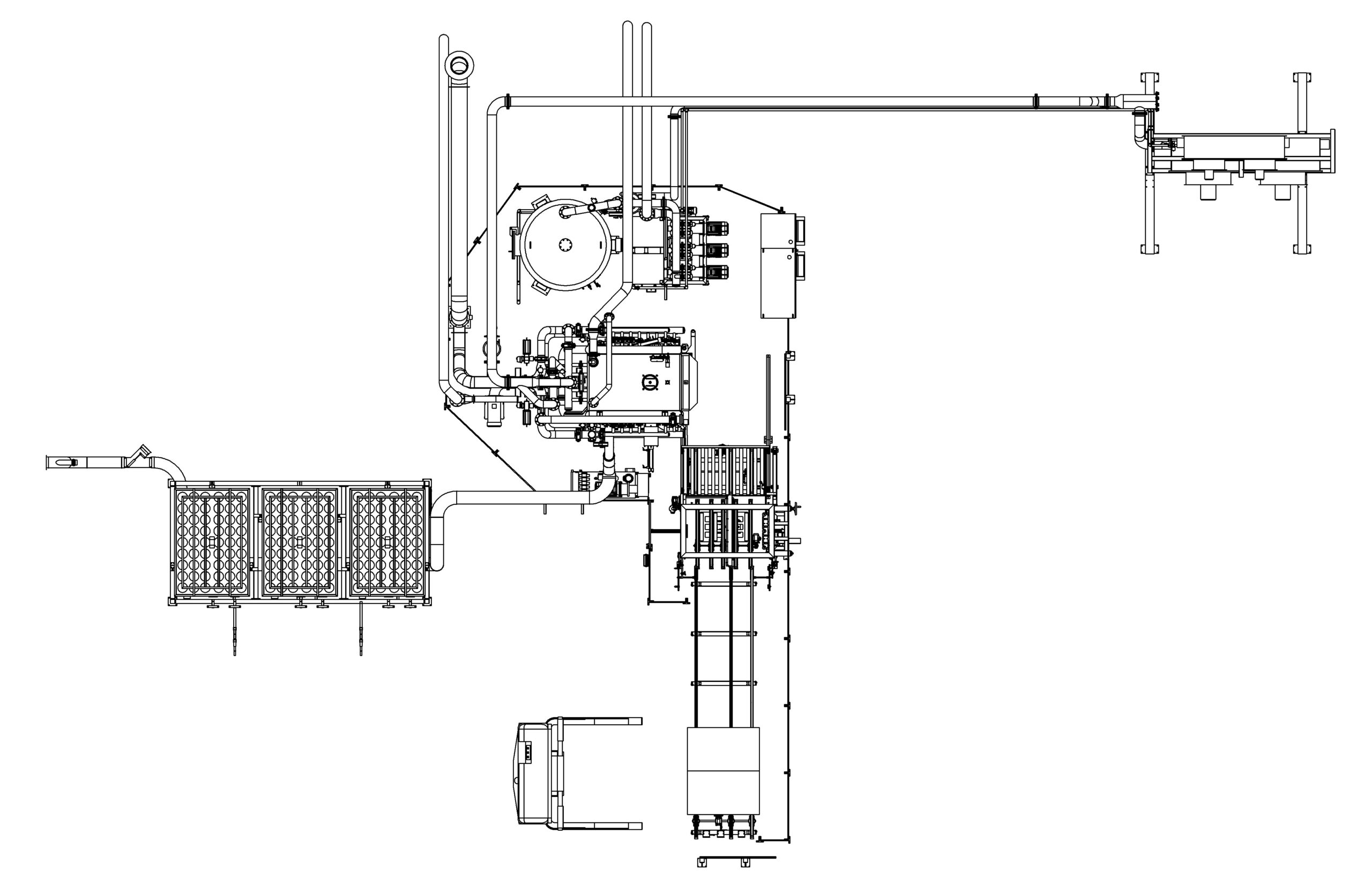

Block moulding machines

Machine to produce expanded polystyrene (EPS) blocks.

Main features

- Designed to mould both virgin and recycled polystyrene achieving block densities between 8g/l and 60g/l. Dosage of recycled material may vary from 0% up to 100%.

- Automatic or manual density correction by means of mechanical compression.

- Automatic cleaning of feeding valves and pipes connecting when switching production between white and grey material.

- PID control loop feedback mechanism for optimization of steaming and energy consumption.

- PED mark according to Directive 2014/68/UE.

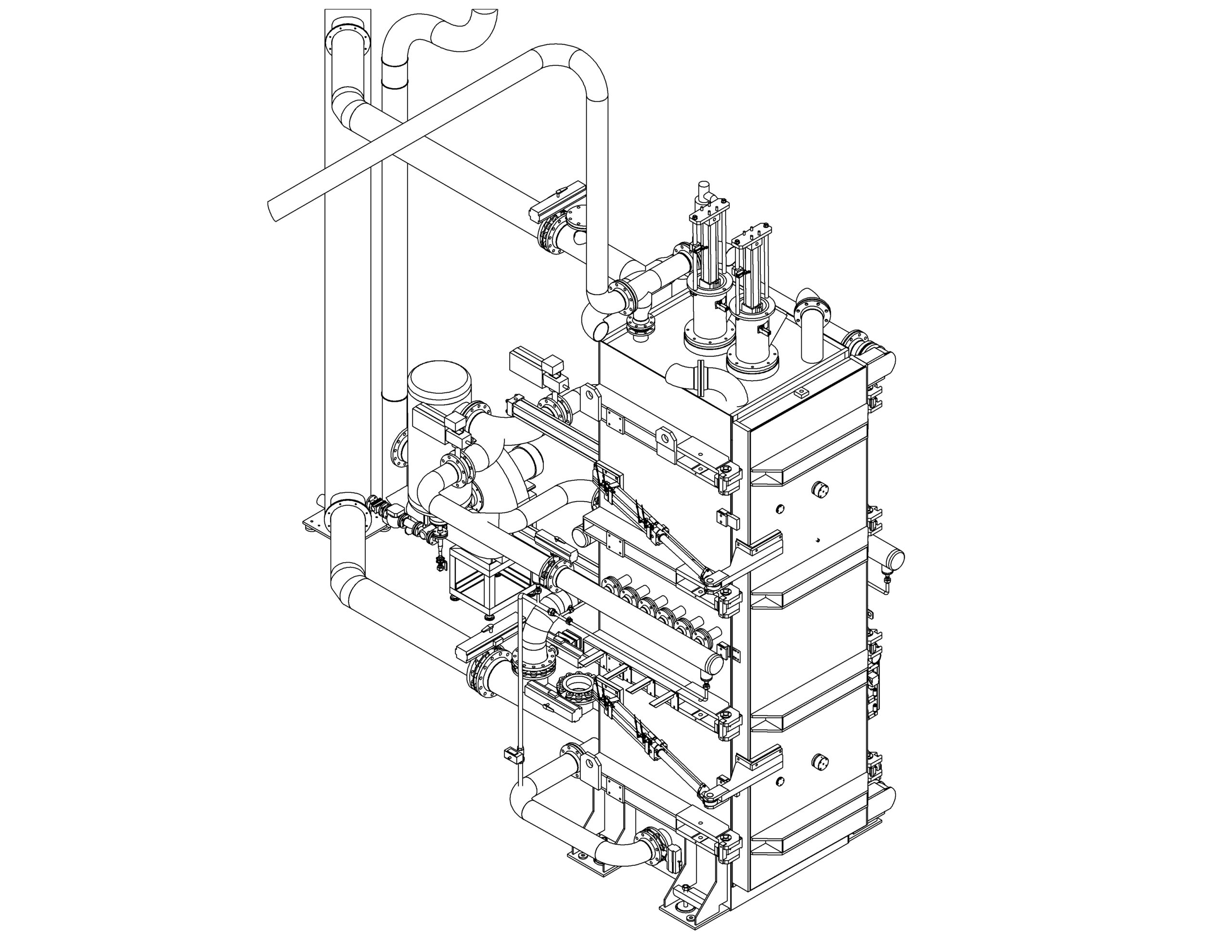

Fixed block moulds

Fixed block moulders, for EPS blocks moulding, are characterized by a sintering chamber with fixed dimensions and not adjustable.

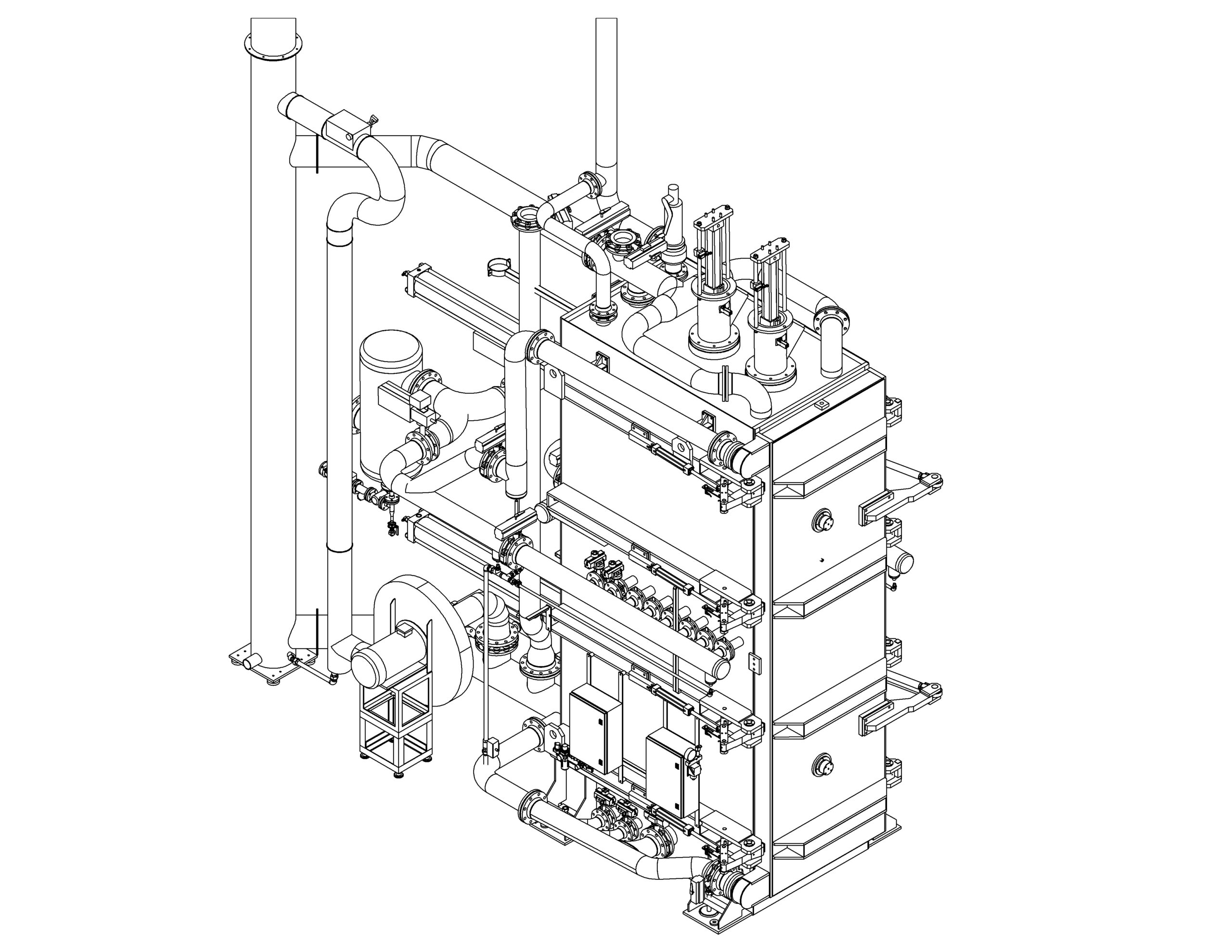

Single size adjustment block moulds

Block moulds are characterized by a sintering chamber with one adjustable wall (back wall or top) to customize block size in depth or in height.

The possibility to adjust the size of expansion chamber allows to optimize block sizes and to minimize scraps in the subsequent converting processes.

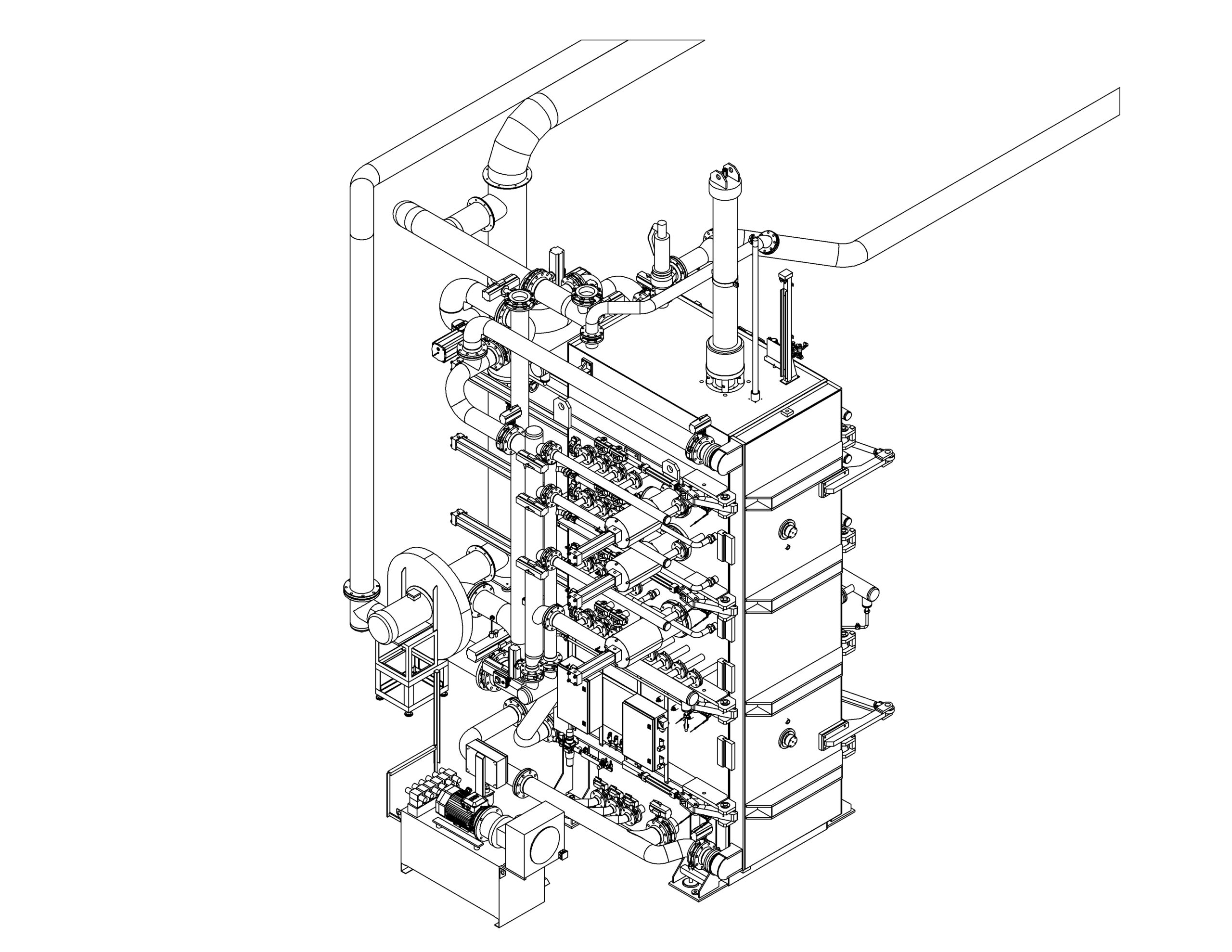

Double size adjustment block moulds

Block moulds having a sintering chamber with two adjustable walls (top and back wall) moving simultaneously to achieve max production flexibility.

The possibility to adjust the size of expansion chamber allows to optimize block sizes and to minimize scraps in the subsequent converting processes.

Optionals

- Vacuum plant.

- Heat recovery system.

- Pentane gas recovery system.

- Pre-feeding silo.

- Automatic density control.

- Mixing plant virgin-recycled material.

- Off-loading unit.

- Block marking unit.

- Block cutting station.

- Automatic magazine.

- Industry 4.0.