RECYCLING MACHINES

Lowest environmental impact thanks to machines suitable for total waste recovery, available as independent solutions or as integrated into the production process.

The scraps generated by the manufacturing process, as well as the dust, can be 100% recycled and reused for subsequent productions.

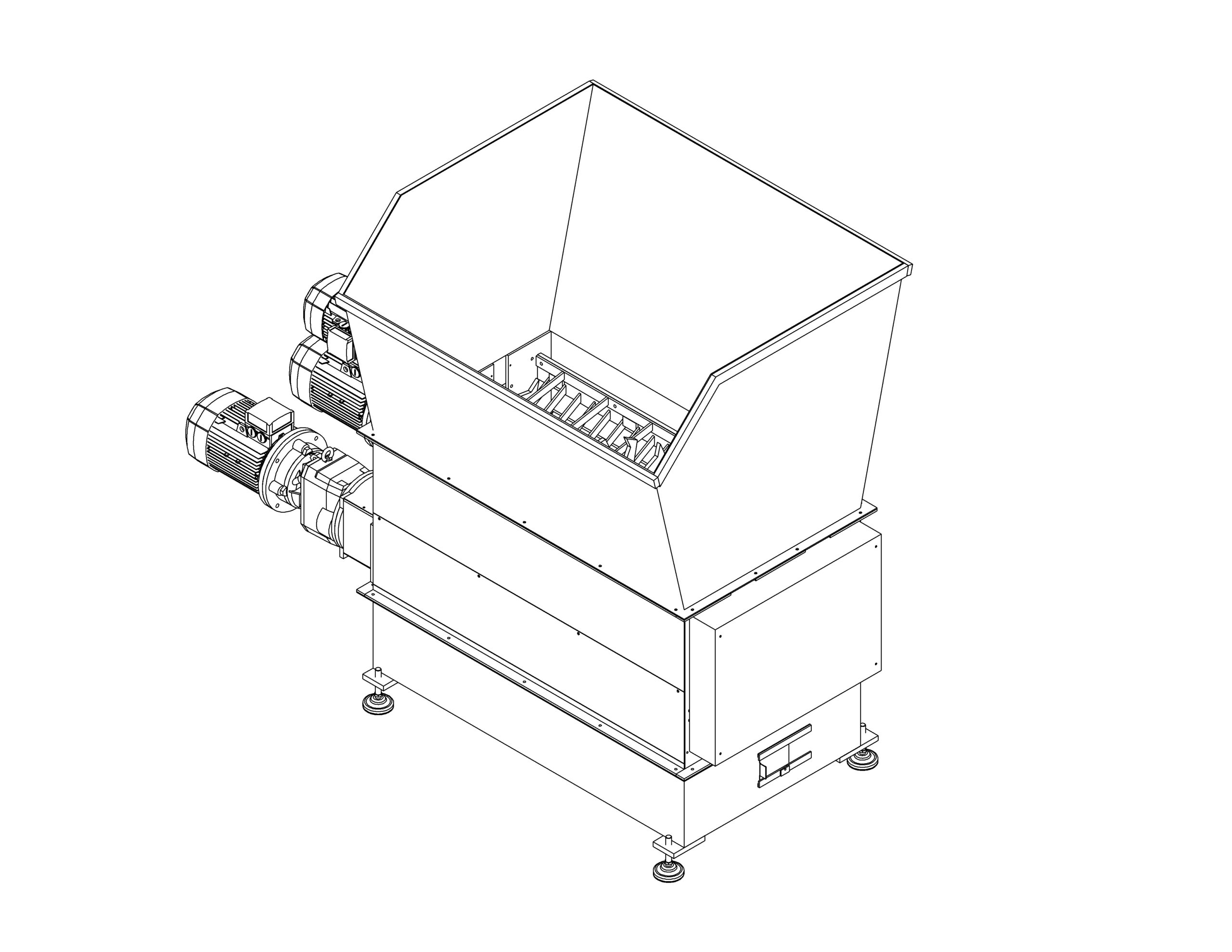

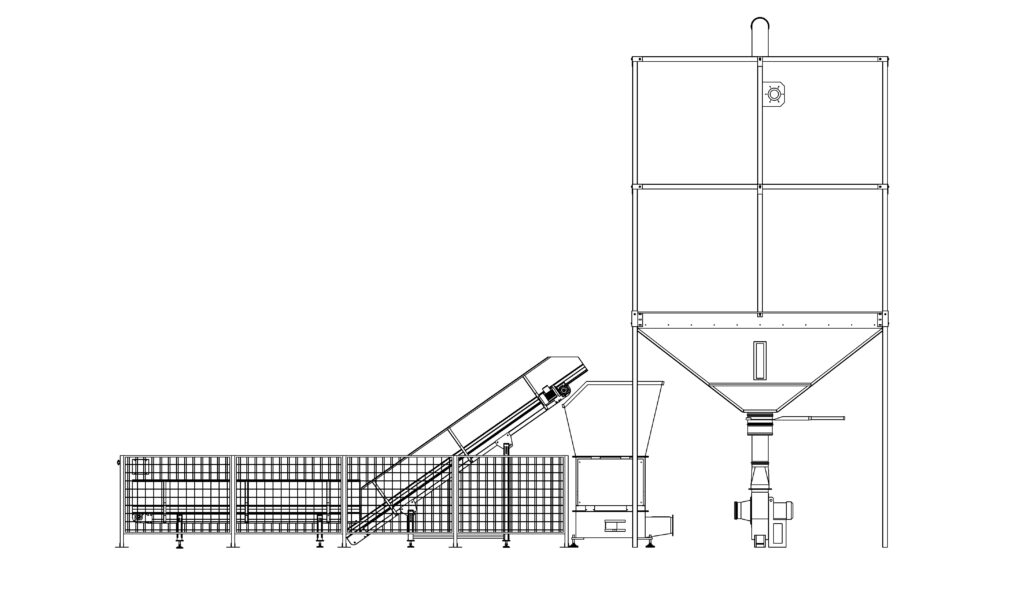

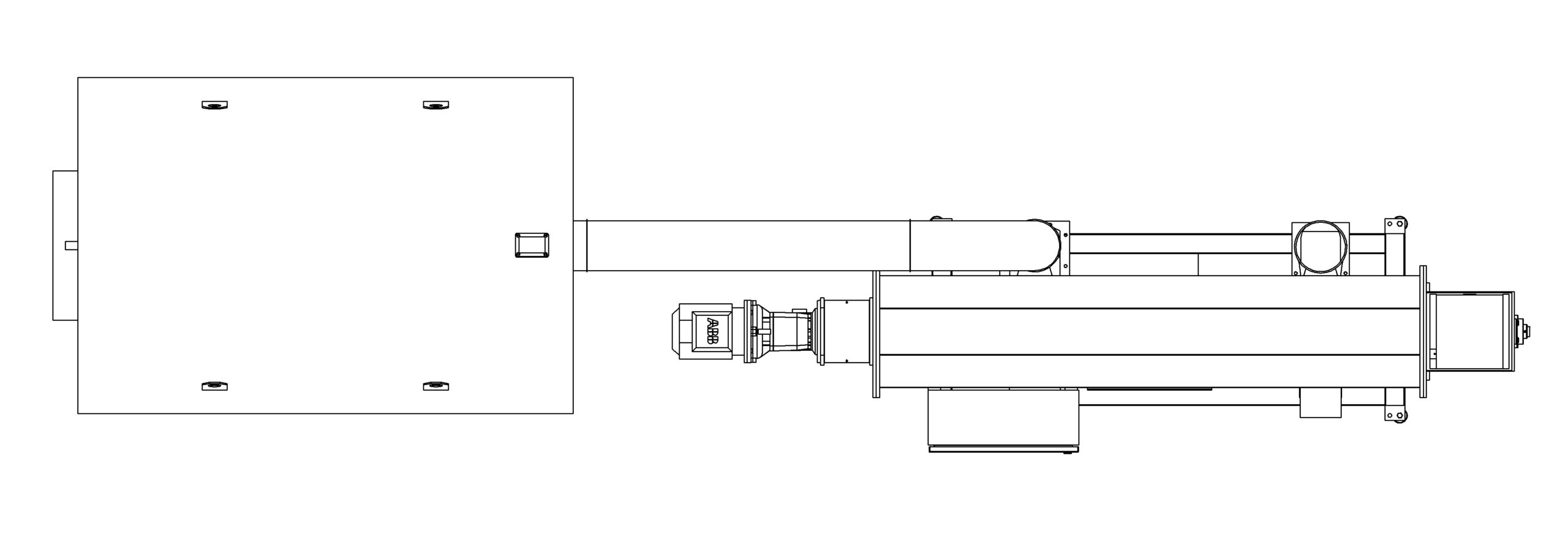

GRANULATORS

Machine to grind expanded polystyrene (EPS) scraps for a subsequent re-use in new block production or other applications.

Designed to guarantee maximum safety for operators and to speed-up the loading of scraps, even of large sizes, thanks to the wide loading area.

The granulators are provided with pre-crusher and knife grinder with interchangeable screens to achieve the desired granulometry, featuring a low noise level.

Optionals

- Storage silo.

- Loading belt conveyors.

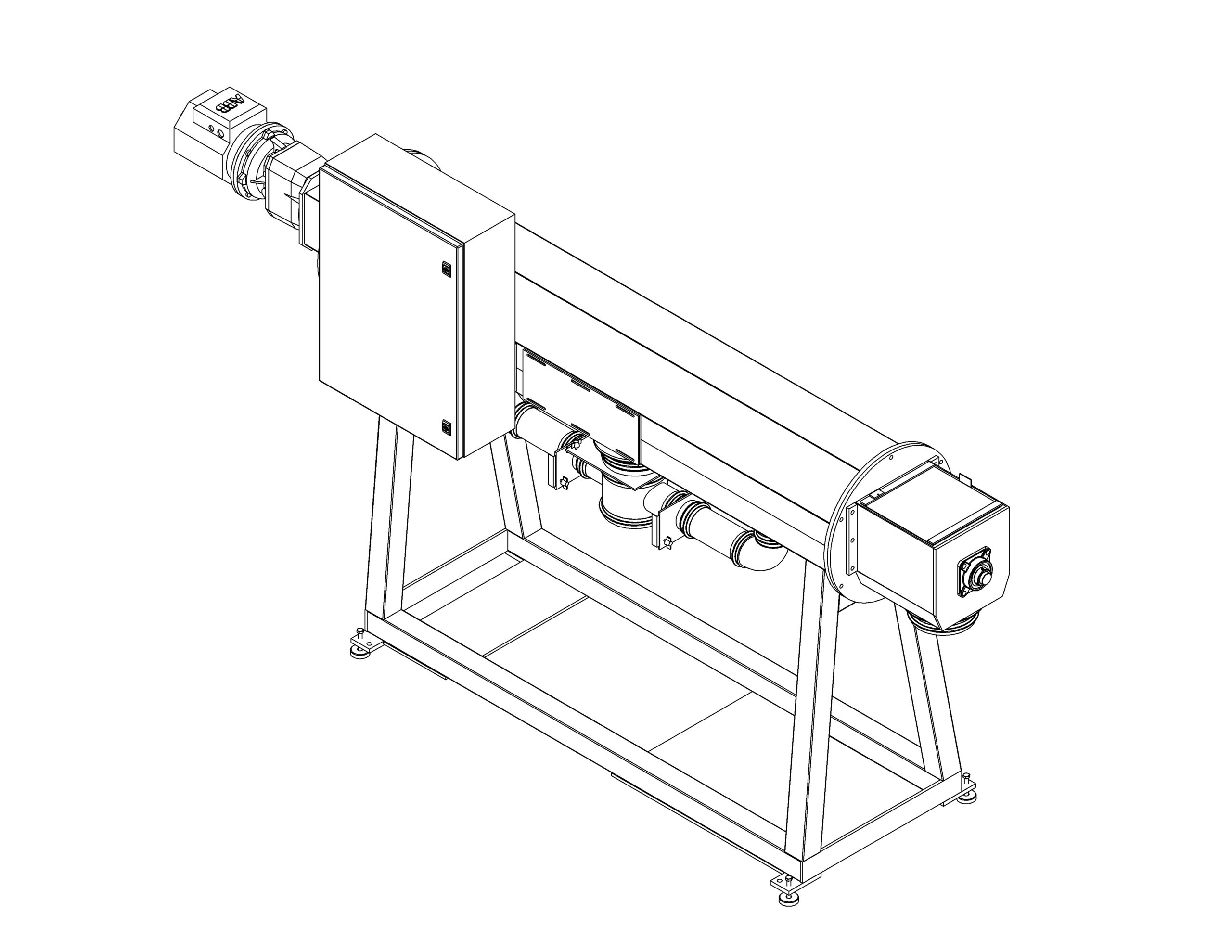

DEDUSTERS

These machines allow to reduce the amount of dust inside the material processed by granulators.

Granulated material is conveyed by a motorized bristle screw feeder through a cylinder filter. The dust is eliminated by means of the vacuum created by the fan.

The dedusted beads are then poured again into a silo by means of a fan while the dust is fully collected by a dust filter, equipped with a thermal detector preventing from fire ignition inside it.

Optionals

- Dust filter.

- Dust compactor.

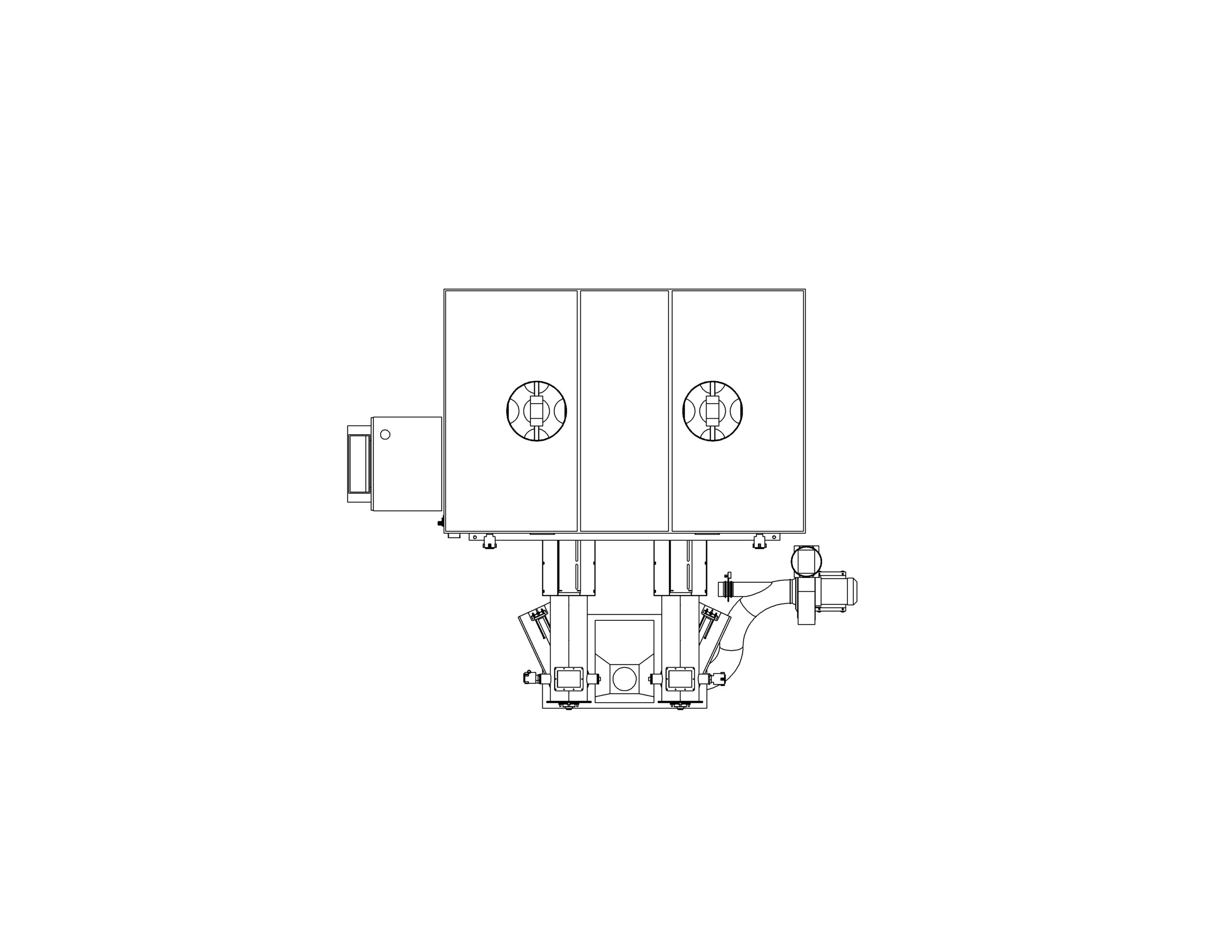

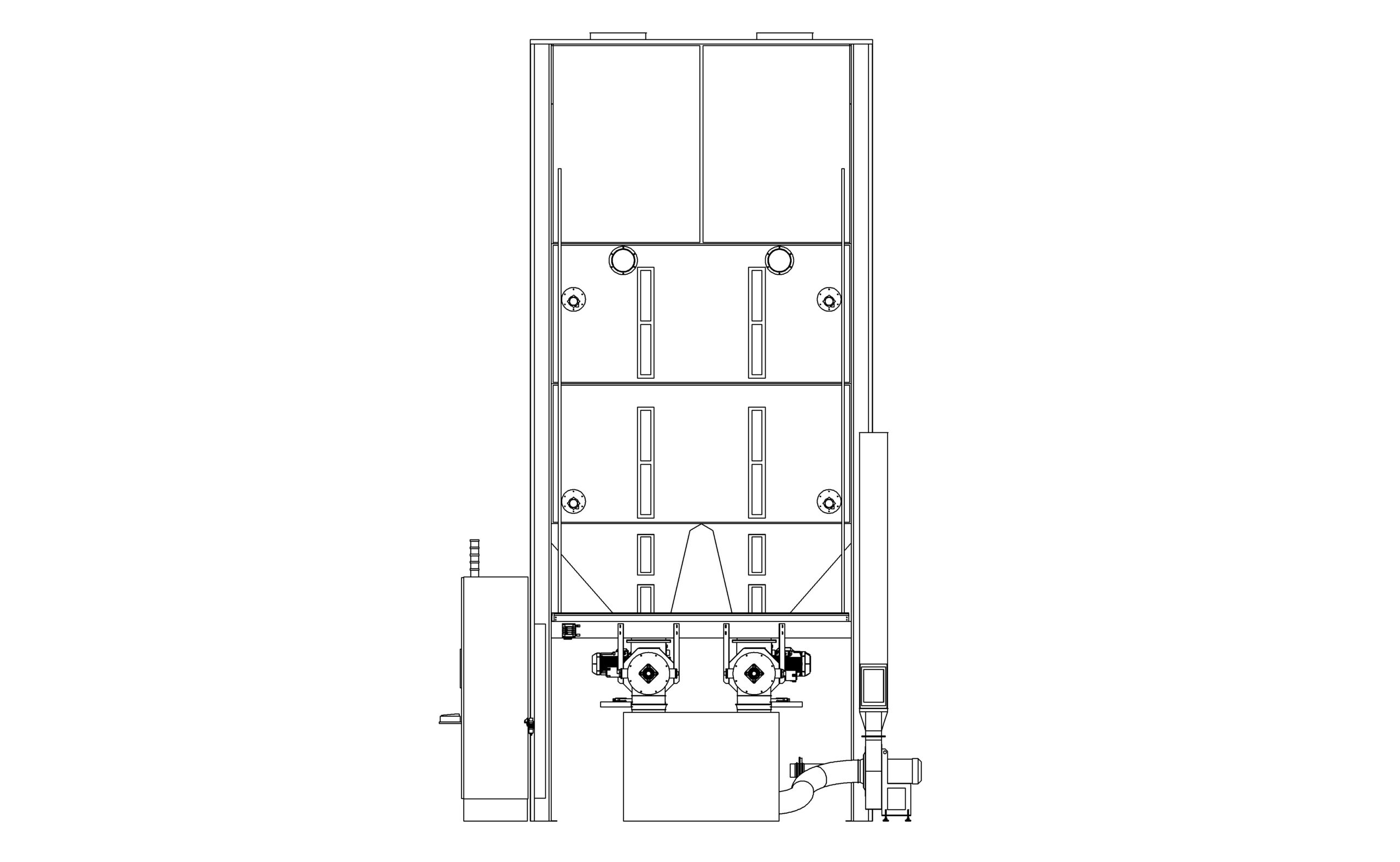

MIXING MACHINES

Machines for mixing virgin with recycled material, equipped for being interfaced to the supervision system of the block mould and silos plant.

The mixing unit consists of two joined silos with level indicators for the automatic management of loading and unloading. Two steel augers are installed on the base. Their rotation speed, electronically controlled by an inverter, allows accurate dosing of the flow rate and mixing percentage.

The augers are provided with indicators for clogging control and can be integrated with systems to dedust the material directly as it flows.

Thanks to the special self-cleaning sock filtering system, the silos manufactured by Tecnodinamica allow the filtering of exhaust air and prevent from releasing dust into the environment. This keeps your production area completely dust-free, providing a safe operator environment that complies with current regulations.

Components

- Silo to store the virgin material.

- Silo to store the recycled material.

- Mixing auger with electronic control.

- Hopper to collect the mixed material.

Optionals

- Automatic connection to pre-feeding silo of block mould.

- De-dusting system integrated with mixing augers.

- Silo to collect the dust.

- Dust compactor.