SLICING MACHINES

Slicing machines are suitable to produce flat and tapered sheets in various thicknesses, performed with high accuracy in tenths of millimeter.

Main features

- Prevention of fire ignition: hot wires automatically switch off when working axes remain inactive for longer than a set time-limit.

- Broken wire detection system with automatic stop of the machine.

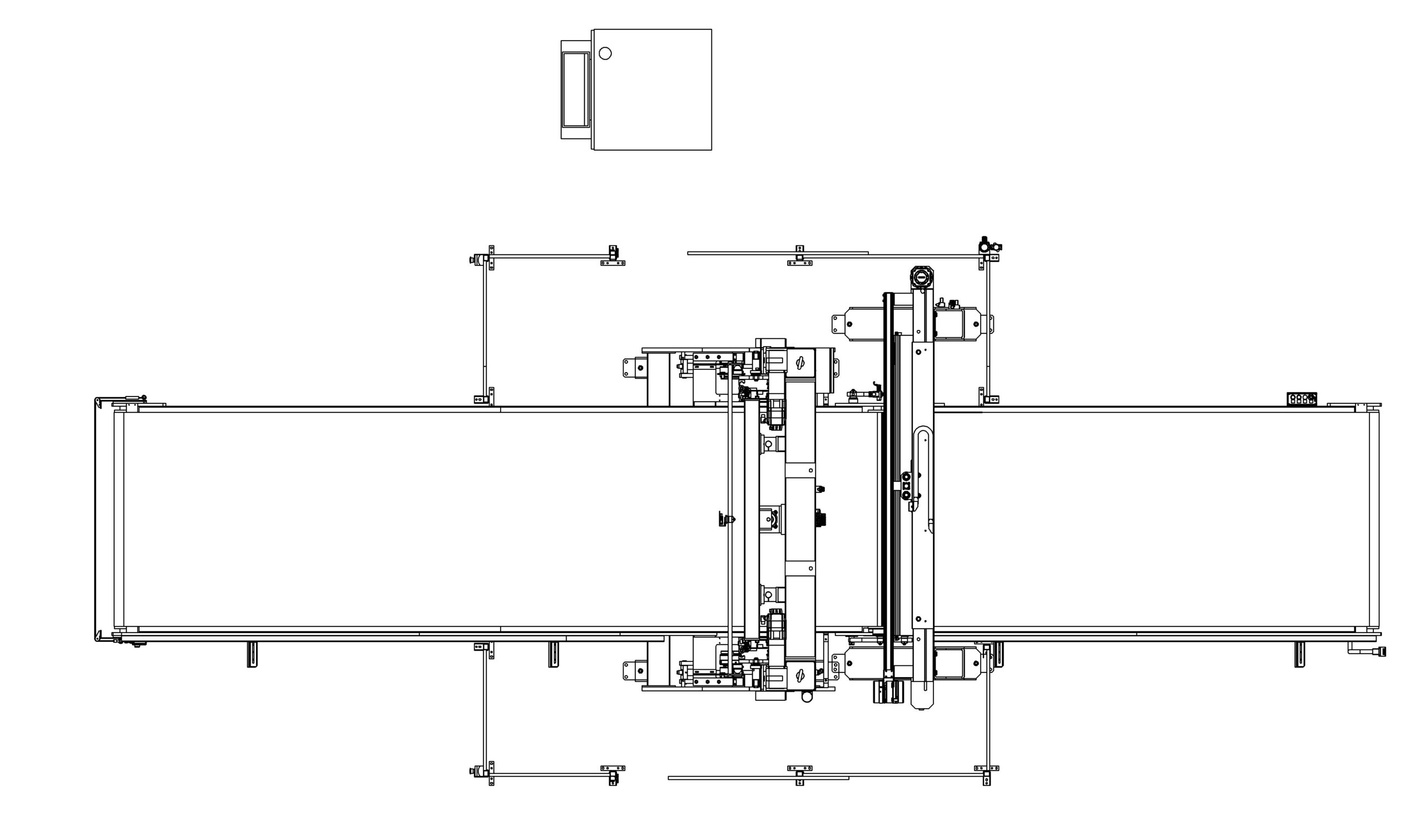

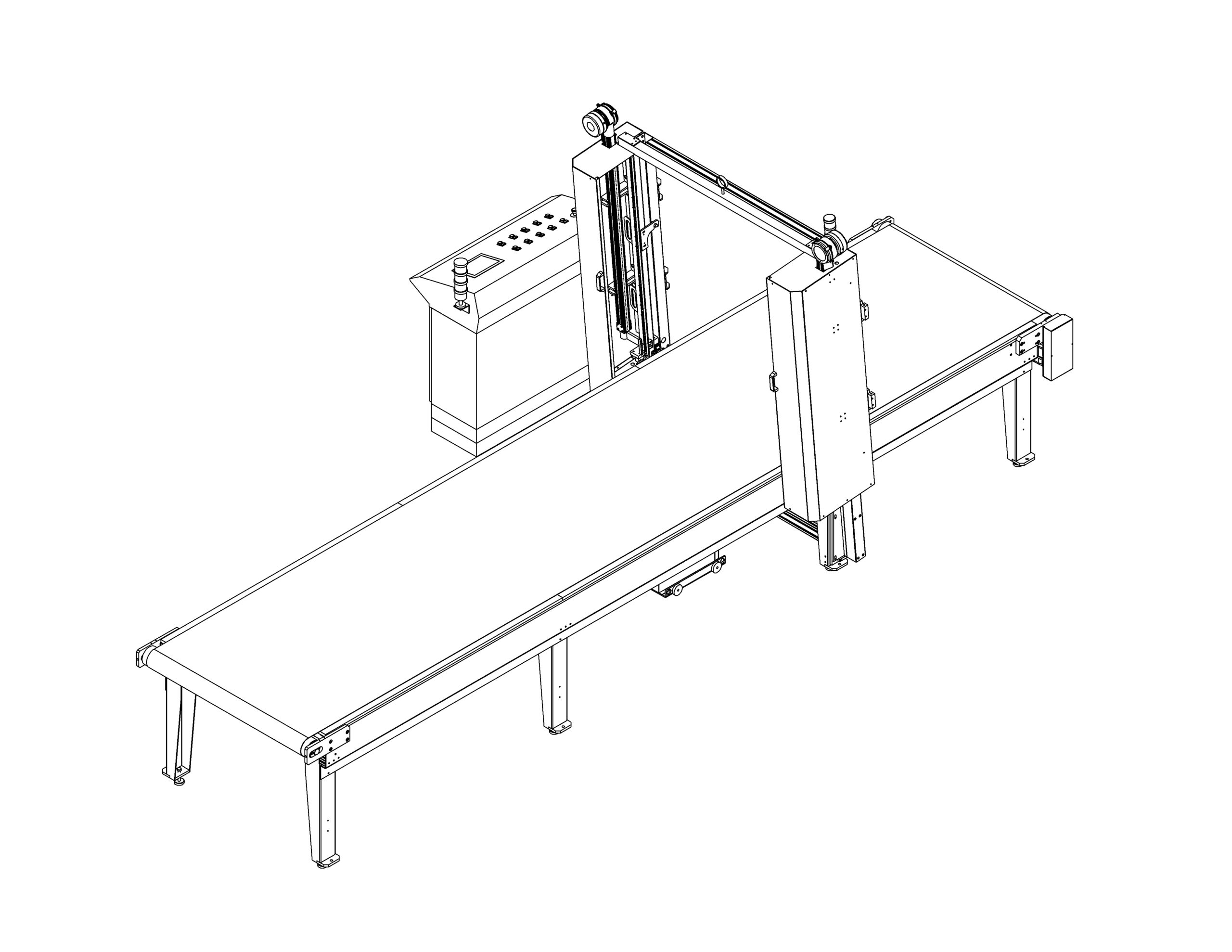

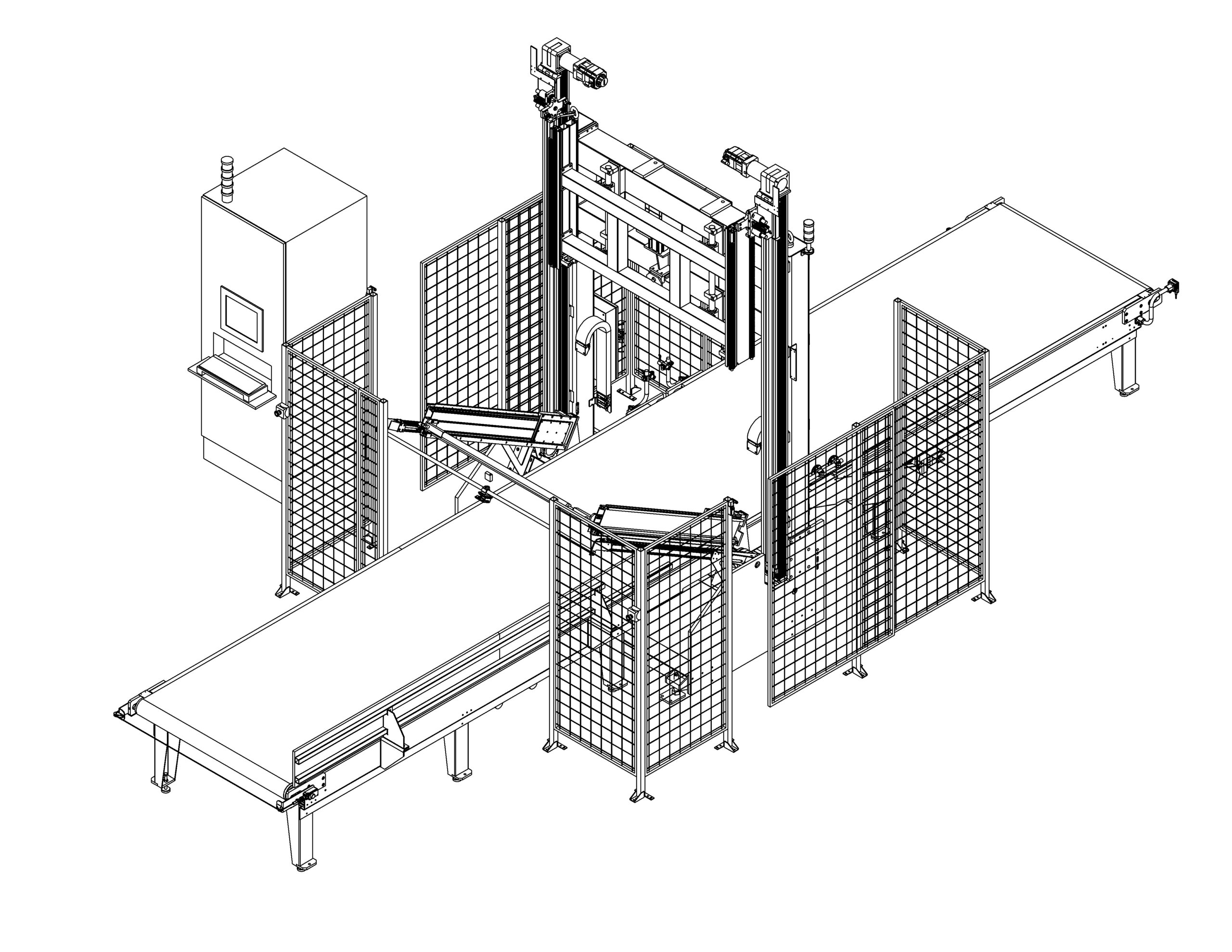

Fixed slicing machines for EPS

Fixed slicing machines are characterized by a belt conveyor, with high friction coefficient, on which the EPS block is placed and by a wires holding frame with fixed inclination.

Fixed slicing machines are available with manual wires setting as well as with automatic wires setting and they can reach a minimum cutting thickness of 8mm.

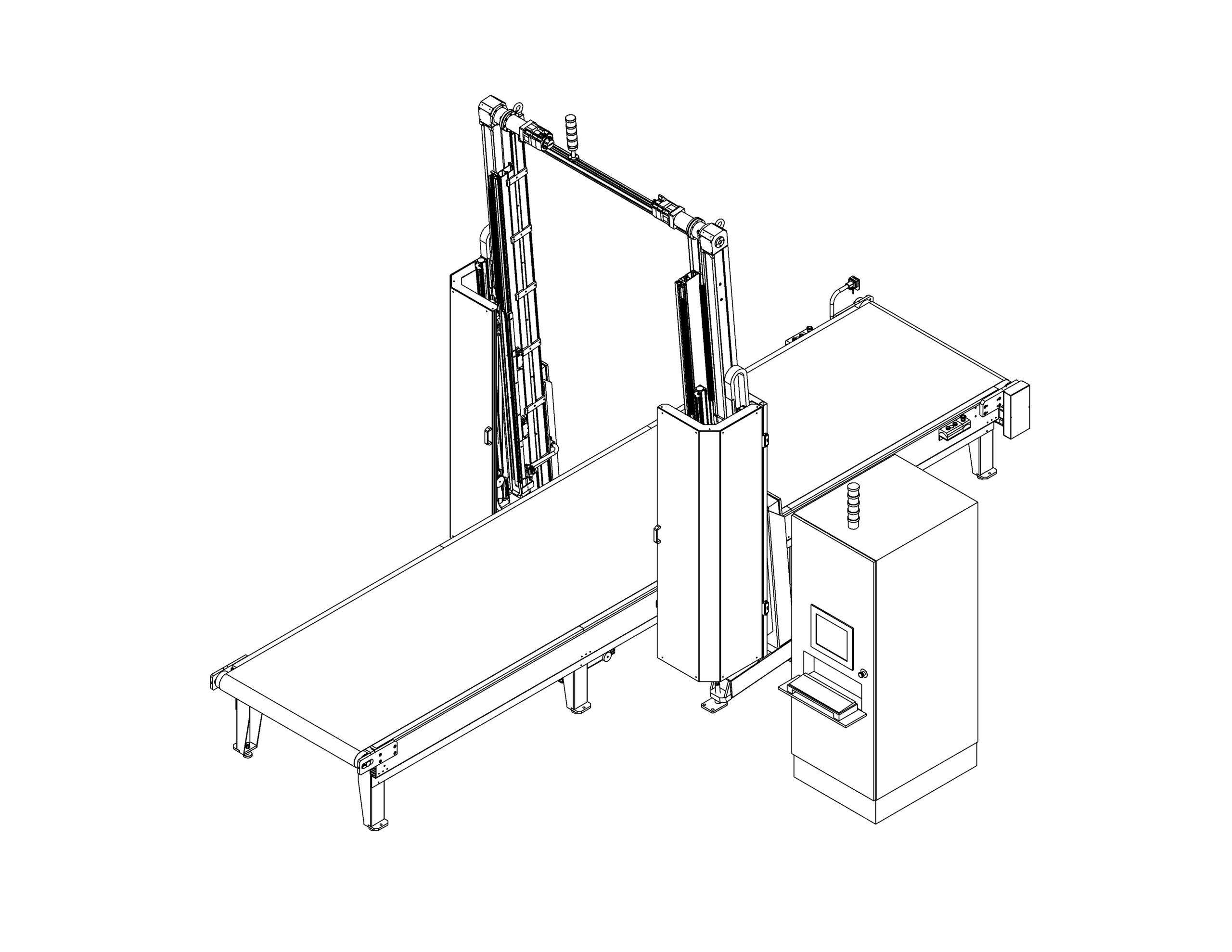

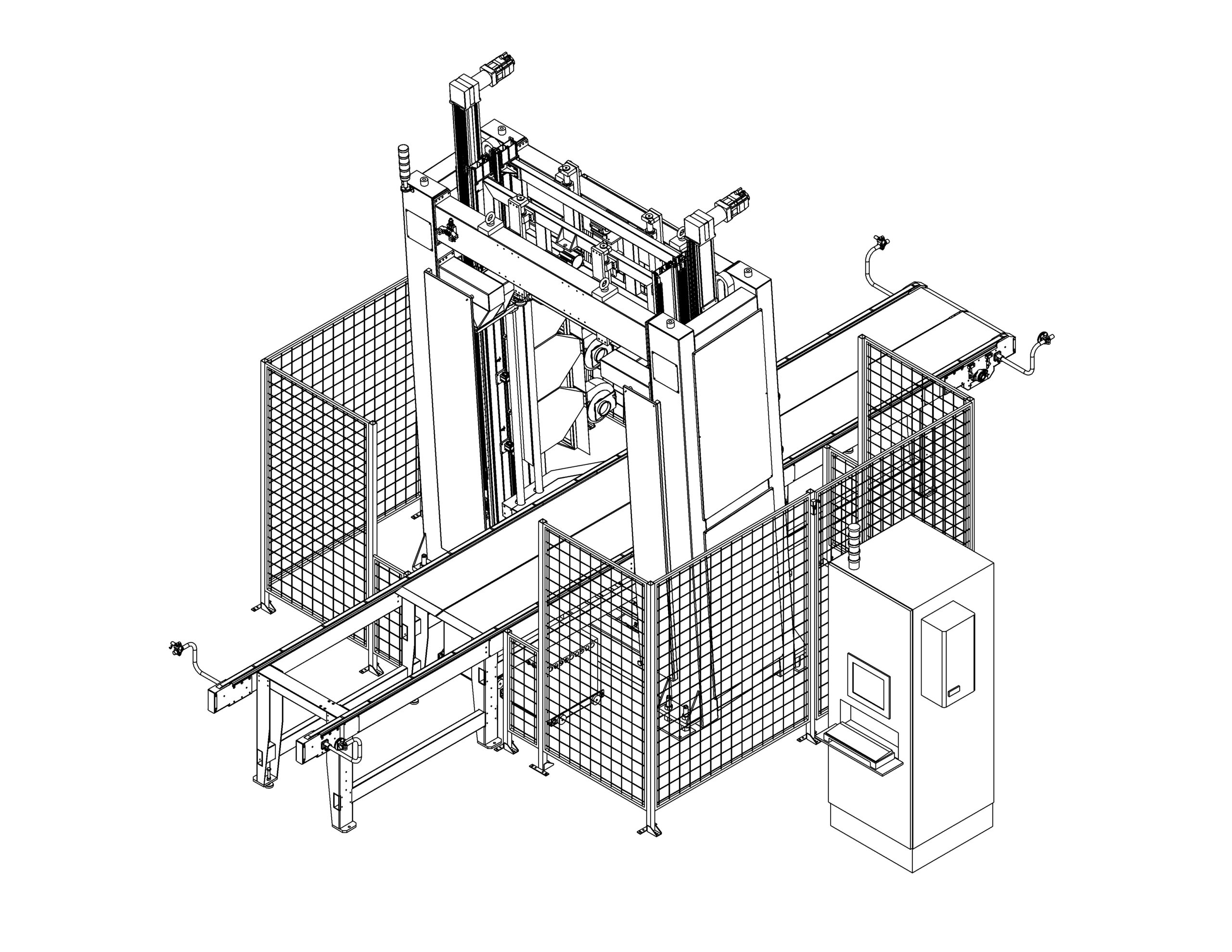

Slicing machines with tilting frame

Slicing machines with tilting frame are characterized by a belt conveyor, with high friction coefficient, on which the EPS block is placed and by a wires holding frame that can be tilted electronically at different angles.

Slicing machines with tilting frame are available with manual wires setting as well as with automatic wires setting. Slicing machines with manual setting are equipped with five interchangeable frames with fixed pitches to allow the cutting of the various thicknesses. These machines can reach a minimum cutting thickness of 3mm.

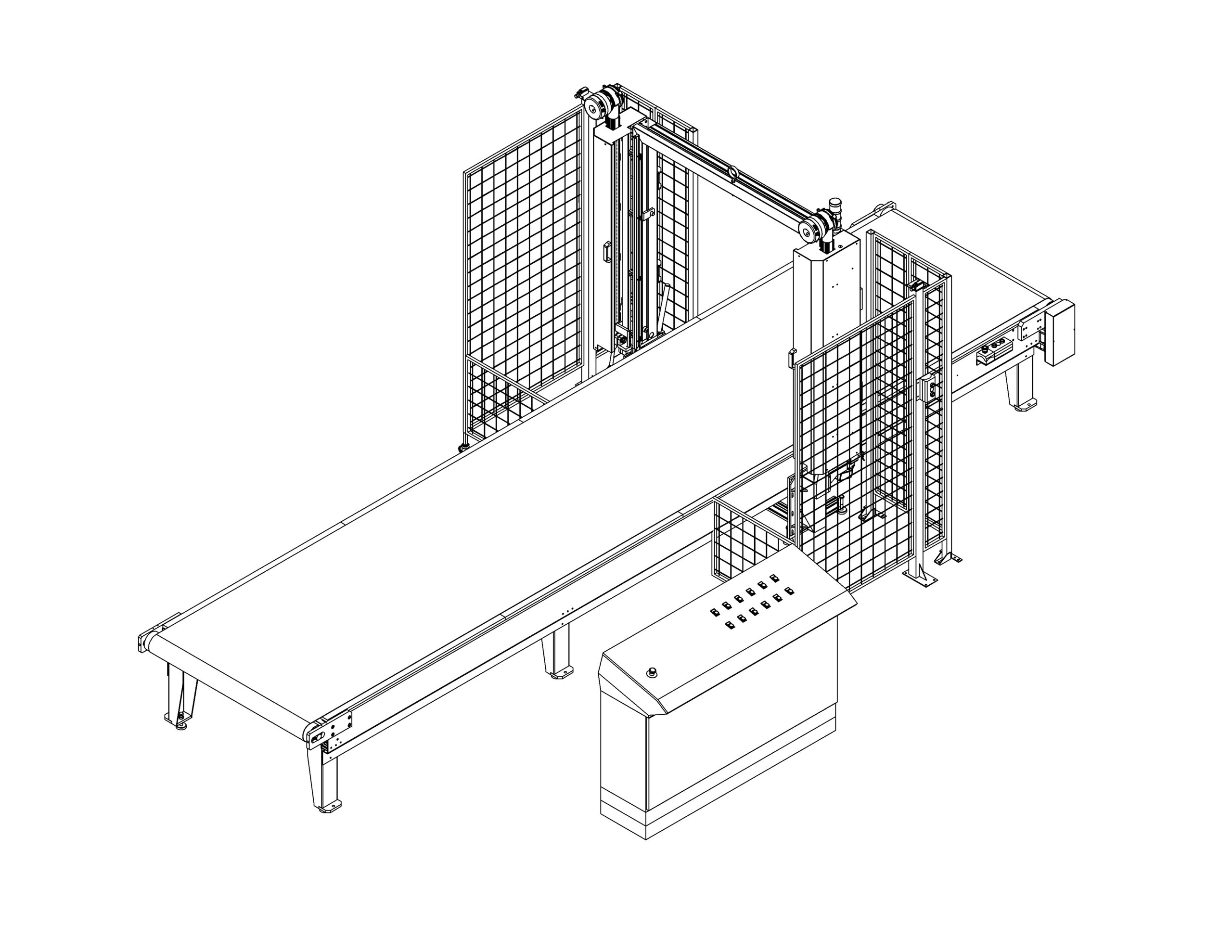

EPS slicing machines with oscillating wires

Slicing machines with oscillating wires are characterized by a chains conveyor on which the EPS block is placed and by a wires holding frame with fixed inclination.

Slicing machines with oscillating wires are available with automatic wires setting and they are the right solution to cut material with graphite additive. Indeed, the oscillating movement prevents the graphite to settle on the wires, avoiding frequent interruption for the cleaning. These machines can reach a minimum cutting thickness of 5mm.

Optionals

- Vertical cutting station.

- Industry 4.0.