WRAPPING MACHINES

The wrapping machines are used for packing insulation boards made of different materials, such as EPS, XPS, PUR/PIR and rock wool. Bundles are wrapped with stretch film on 4 sides or on all 6 sides guaranteeing maximum protection for the wrapped material.

Main features

- Excellent film bonding and perfect bundles sealing, thanks to the unique design of the welding bars.

- Supervision and control fully integrated with Tecnodinamica’s processing machines.

- Highly efficient, designed for mass productions.

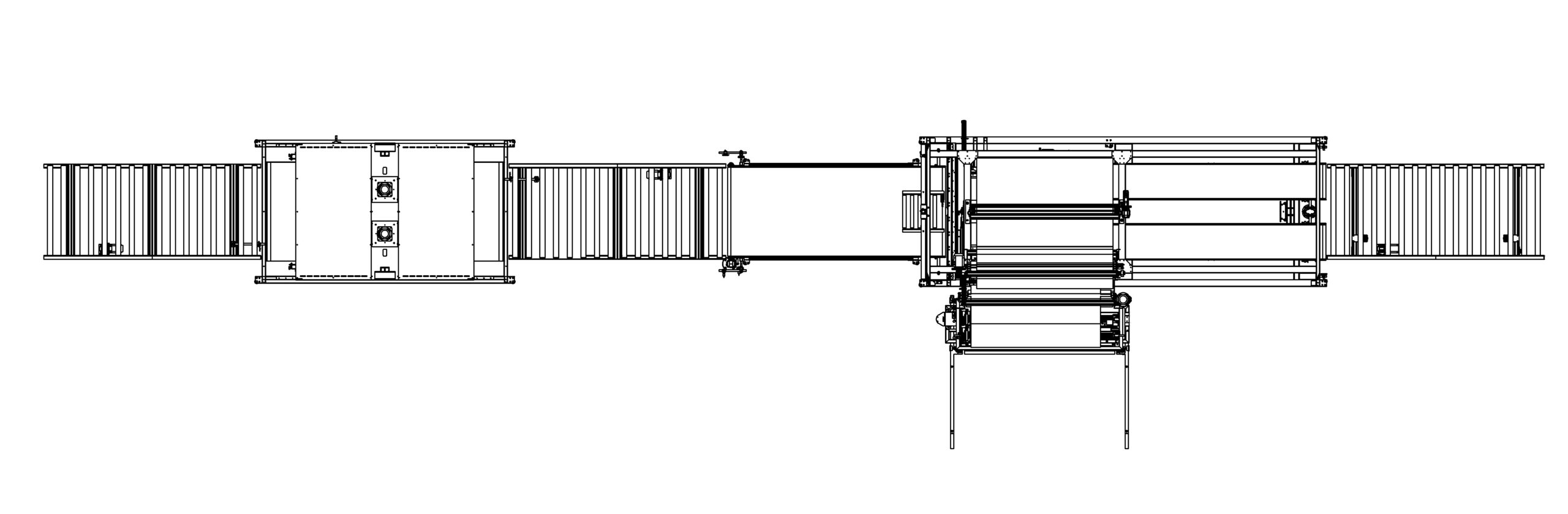

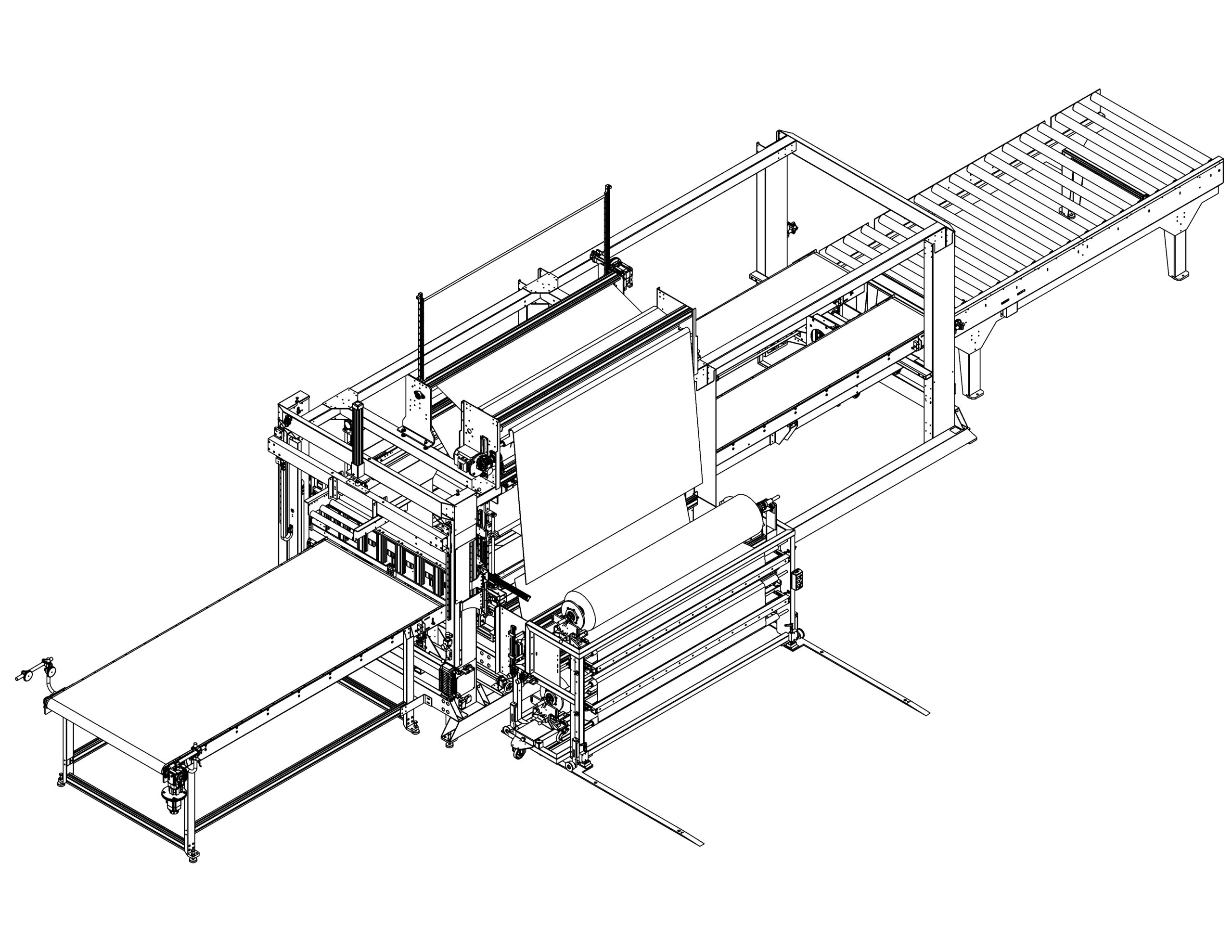

FILM-PULLING MACHINES

The film-pulling serie are machines for packing on 4 sides, by pushing the bundle against a stretched polyethylene film and then welding the film at the end of the bundle.

These machines are characterized by a high packing speed and by a lower film and energy consumption.

Optionals

- Rolls magazine.

- Retractable pusher.

- Industry 4.0.

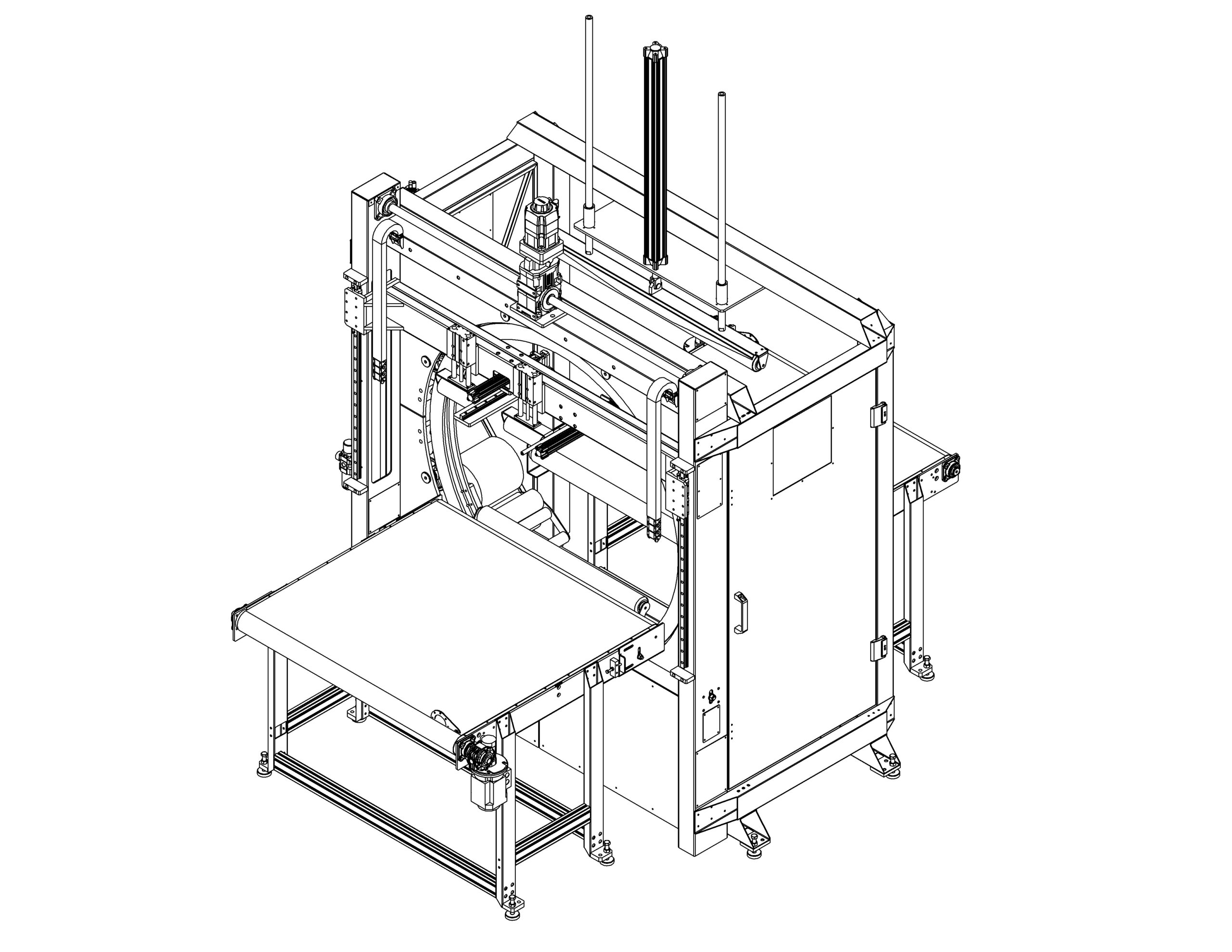

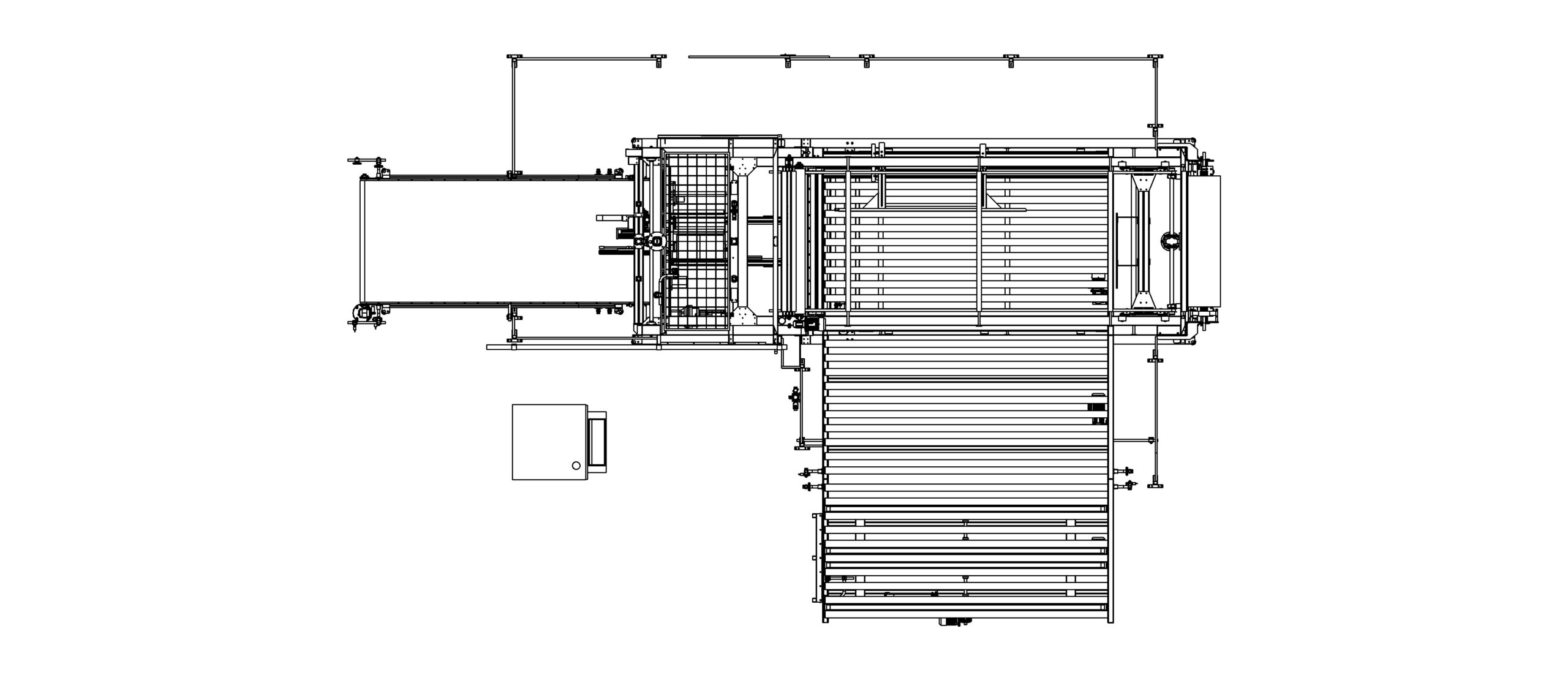

ORBITAL MACHINES

The orbital series are machines for packing on 4 sides, where the bundle is wrapped by a rotating polyethylene film roll.

These machines allow to pack very long products, giving high stability to the wrapped bundles. Furthermore, they allow to wrap products both for the entire length, as well as a partial wrapping in order to reduce the film consumption.

Optionals

- Bridge conveyor.

- Upper cutting and welding unit.

- Skids applicator.

- Industry 4.0.

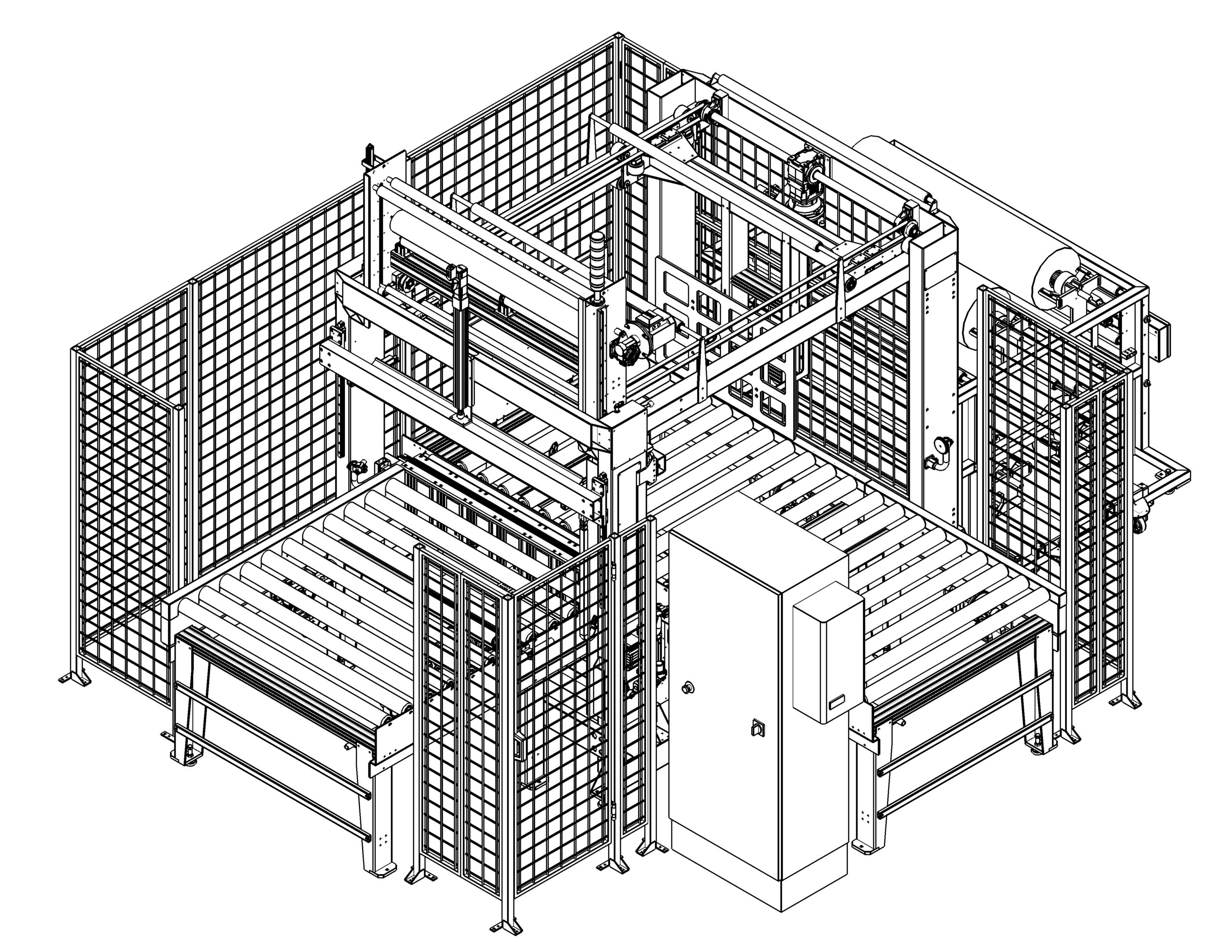

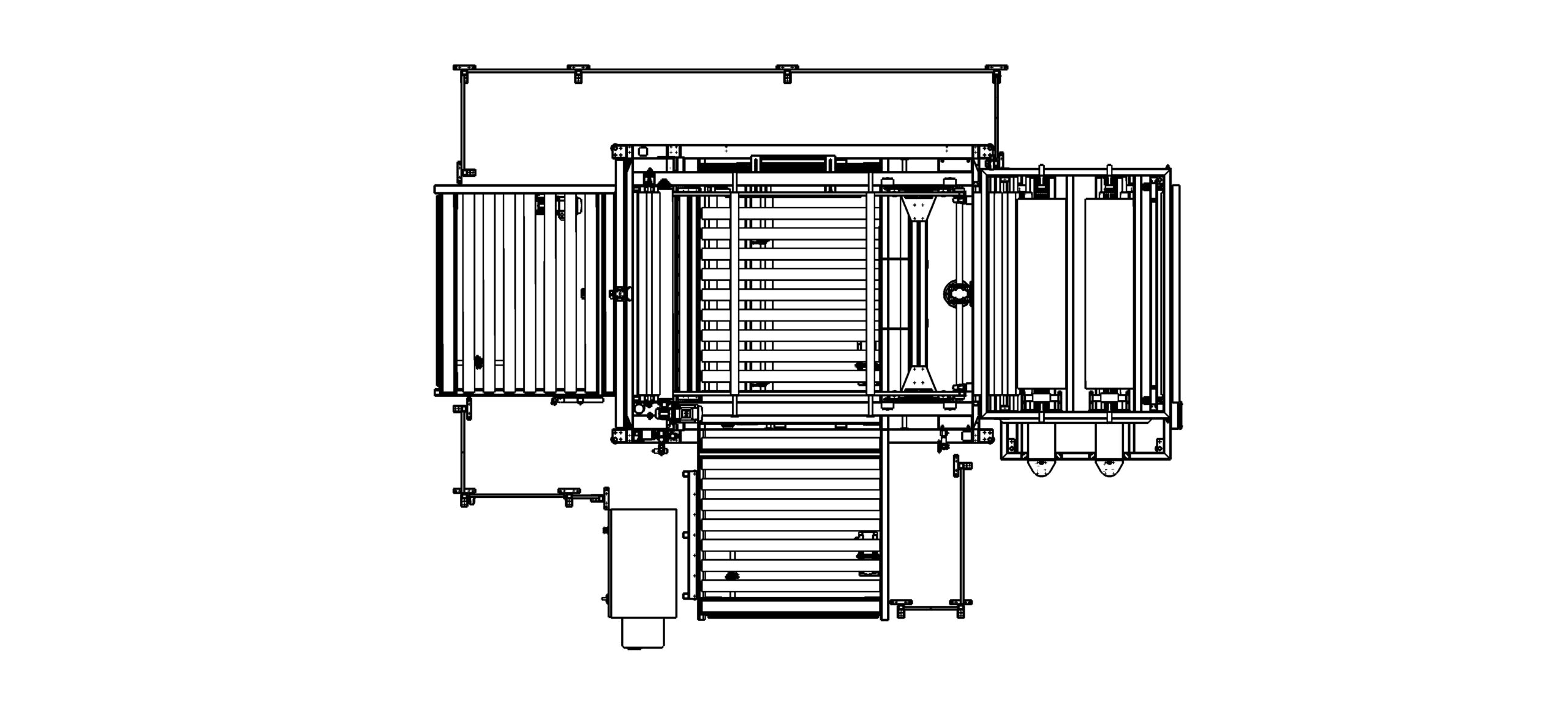

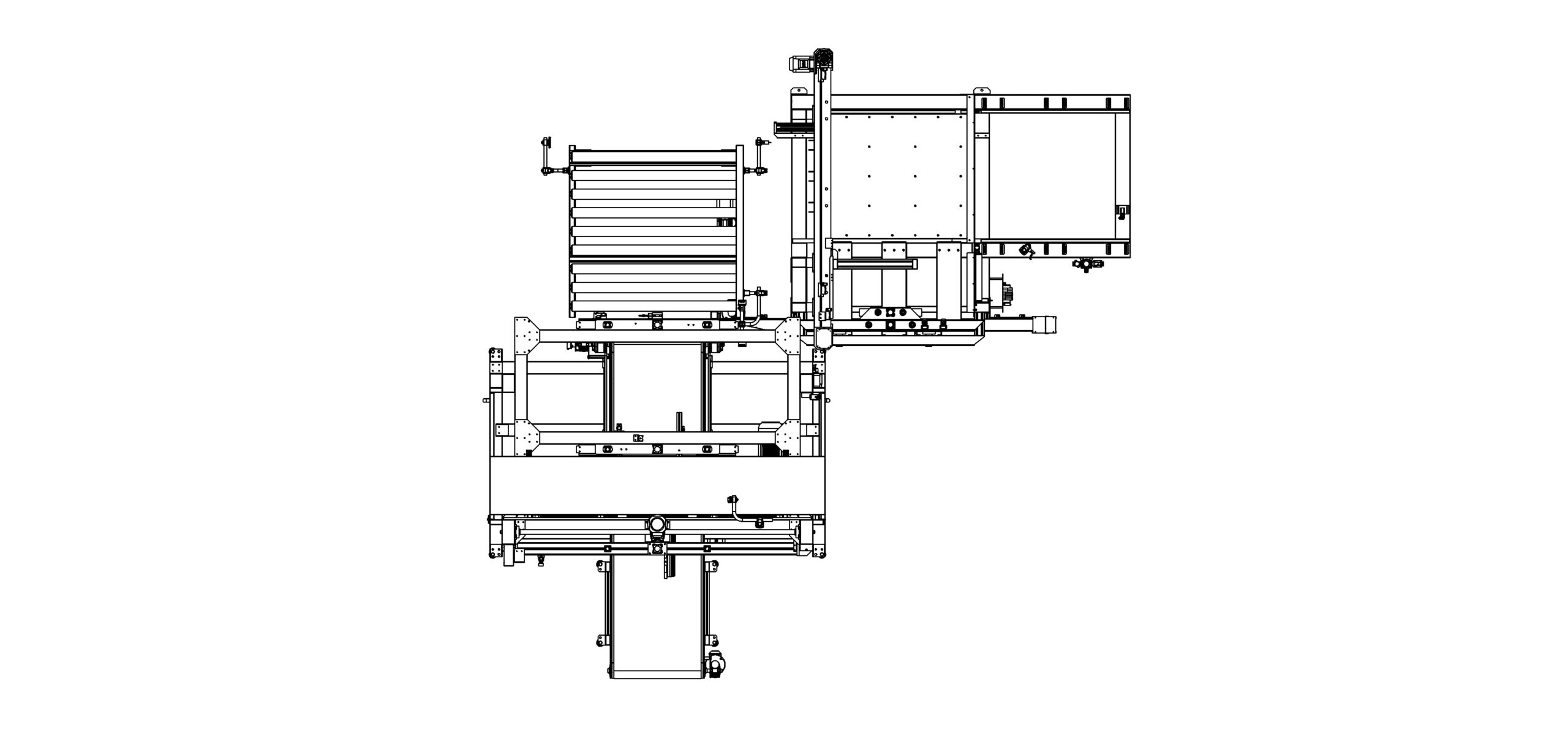

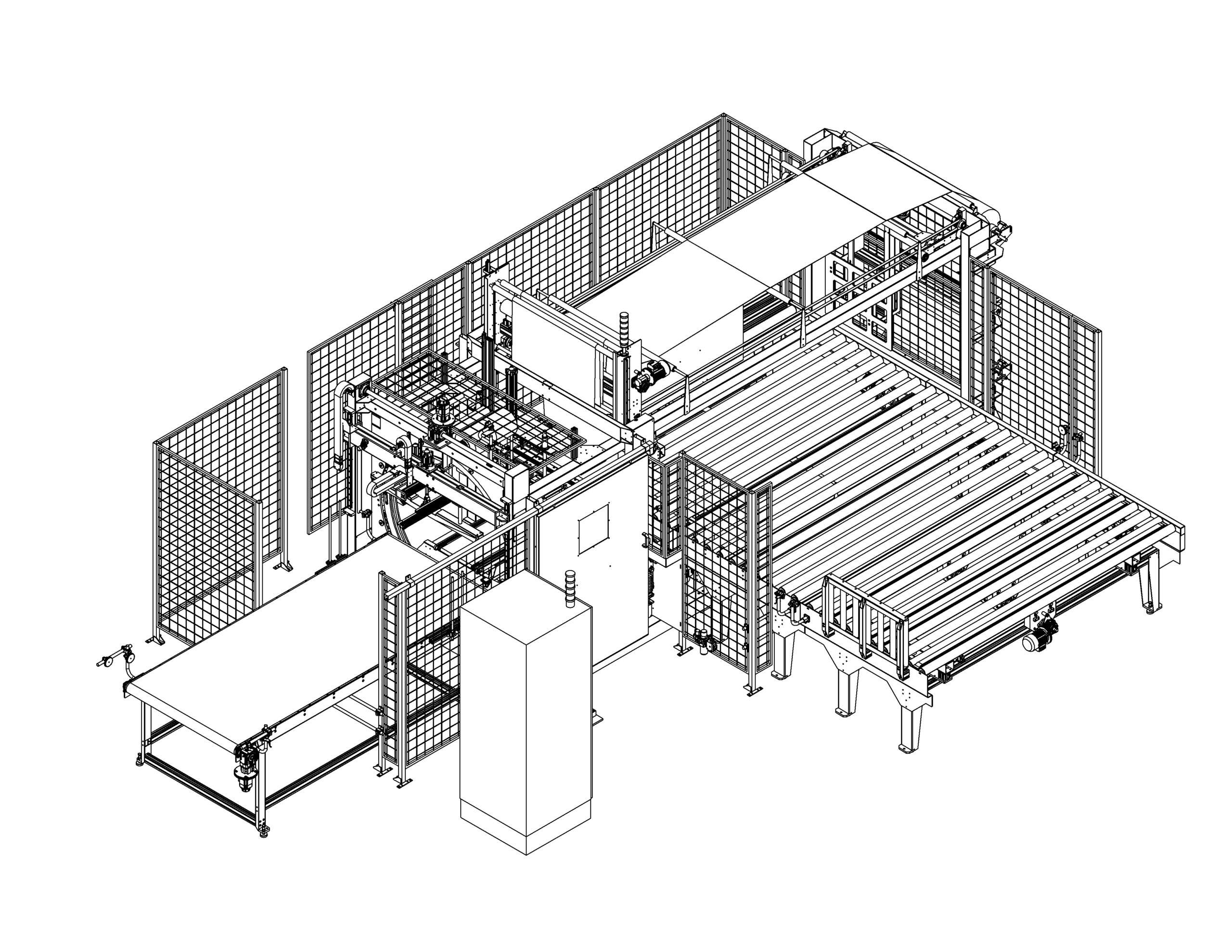

COMBO MACHINES

The combo series are machines for the packing on 6 sides, with two winding stages. The first stage wraps the bundle pushing it against a stretched polyethylene film and then welding the film at the end of the bundle. The second one wrap the bundle in the other direction by a rotating unit holding the film roll.

These machines allow to wrap small and big size bundles, both on 4 or 6 sides, ensuring perfect stability of the wrapped product for every size. Furthermore, the missing of the shrinking tunnel drastically reduces the energy consumption compared with bag systems.

Optionals

- Rolls magazine.

- Retractable pusher.

- Industry 4.0.

BAG SYSTEM MACHINES

The bag systems are machines for the packing on 6 sides, by placing the product inside a polyethylene film bag. The bag, automatically formed by the machine when the products have being put in, can be subsequently heat-shrunk passing the products through special units.

These machines are suitable for packing big sizes bundles, where there is the need of fully protect products from weather.

Optionals

- Double rolls holder.

- Hot air blowers.

- Shrinking tunnel.

- Industry 4.0.